Tel

139-1322-1199

2023-06-28

First, the power indicator of adsorption dryer is not on

1. If the power supply is not connected, check the voltage on the circuit terminal board;

2. The switch is placed in the closed position and the switch is placed in the open position;

3. If the switch fails, replace the switch;

4. The indicator light is burned. Replace the indicator light.

Second, the dew point at the outlet of adsorption dryer is too high

1. Exceeding the larger flow value and exceeding the design conditions;

2. Desiccant has no adsorption effect;

3. The service life has ended;

4. The desiccant has been polluted (such as oil pollution);

5. Premature saturation (excessive water absorption);

6. Liquid water is removed without pretreatment before the airflow enters the dryer.

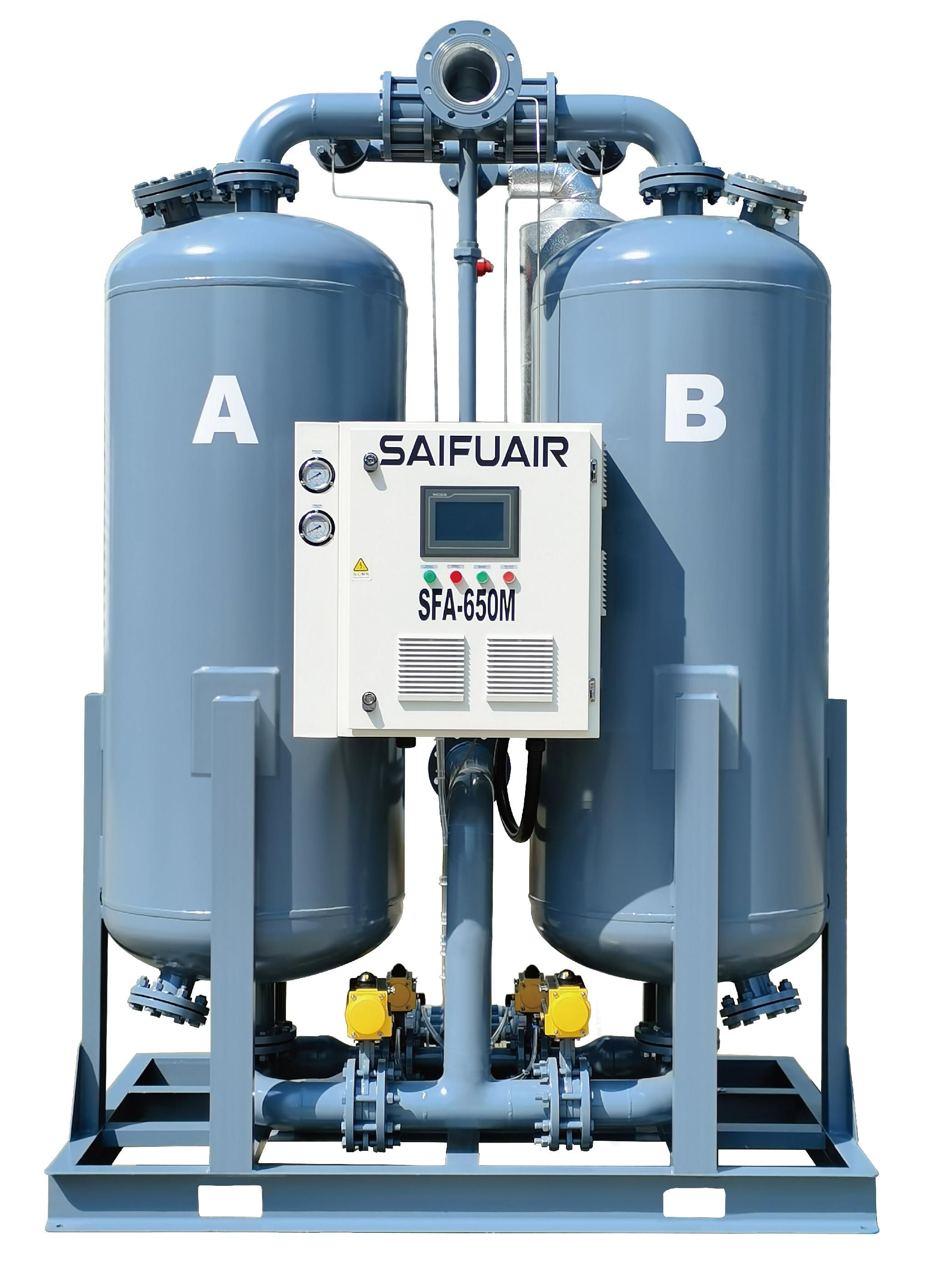

Zero gas consumption blast regeneration adsorption dryer

Third, the desiccant is saturated prematurely

1. Insufficient regeneration rate;

2. The regeneration air valve cannot be discharged;

3. During the regeneration cycle, the pressure of the working tower did not drop completely, I could not drop below 2kgf/c ㎡), resulting in too small pressure difference;

4. The exhaust silencer is blocked;

5. The exhaust valve cannot be opened;

6. The one-way valve is stuck and cannot be closed normally: improper setting and timer failure.

Fourth, the working tower pressure of adsorption dryer can not reach the system pressure

1. The regeneration/booster valve cannot be closed;

2. The demand for downstream air is too large.

Zero gas consumption compression heat regeneration adsorption dryer

Five,The regeneration tower pressure of adsorption dryer cannot be reduced to below 2kgf/c ㎡

1. The silencer is blocked;

2. One-way valve failure;

3. The exhaust valve is opened for too long;

4. The regeneration/booster valve cannot be opened.

Six, Excessive discharge of regenerated gas during regeneration cycle of adsorption dryer

1. The intake valve cannot be closed;

2. One-way valve failure.

Micro-heat regeneration adsorption dryer

Seven, adsorption dryer two towers can not circulate regeneration and drying

Two columns of adsorption dryer can not be recycled and dried, which will cause one tower to regenerate continuously, while the other tower will work continuously. The working tower is full of water due to overload, and the outlet dew point temperature will continue to rise until it exceeds the designed dew point temperature requirement.

1. Failure of intake valve, regeneration valve and booster valve: Check the working condition of all valves, repair or replace relevant valves.

2. The pressure switch in the electric control box fails;

3. Replace the pressure switch;

4. If all working conditions of the machine are normal and all valves are working normally, the pressure switch can be shorted (i.e., bypassed) for emergency.