Tel

139-1322-1199

2023-09-06

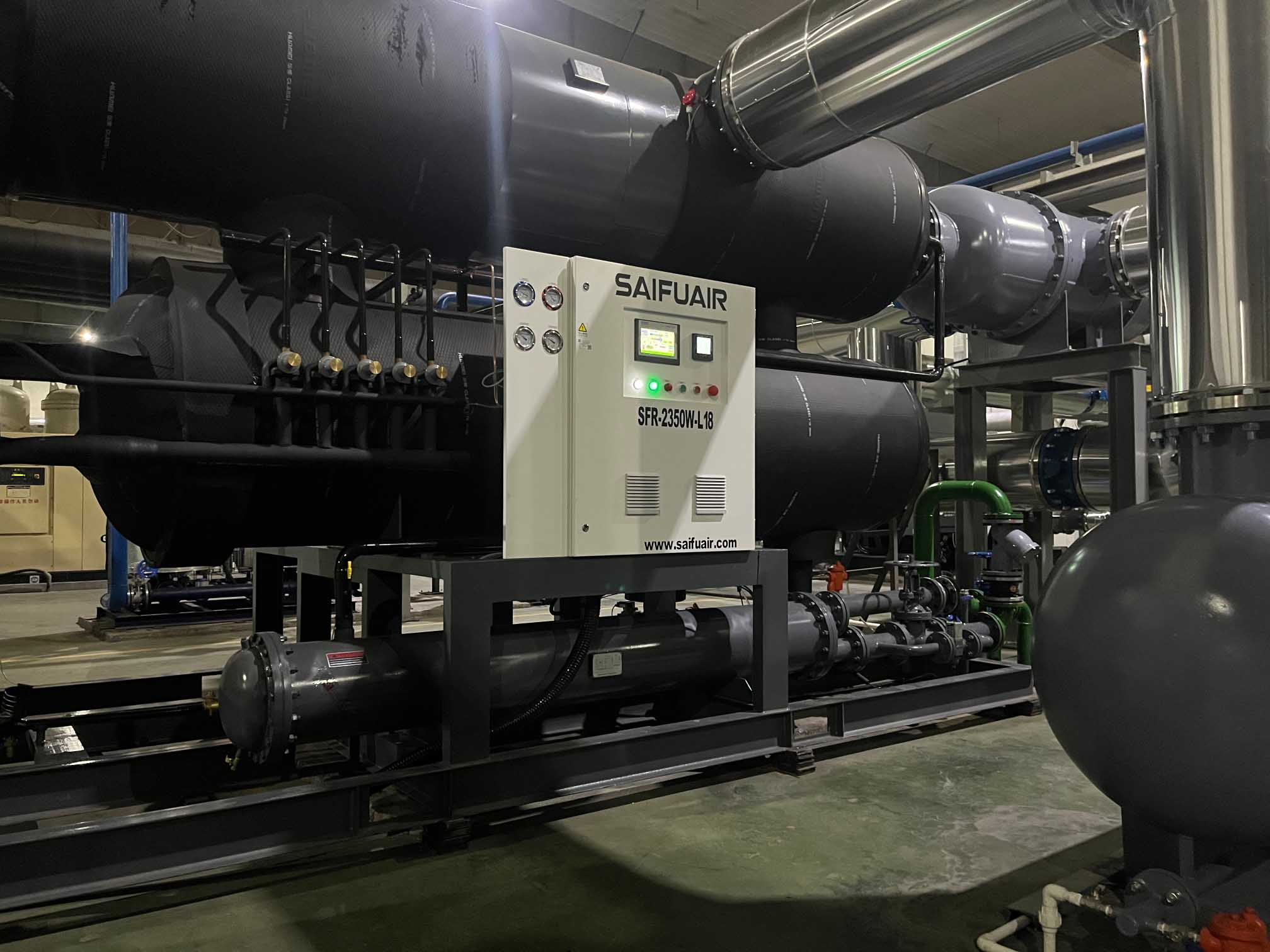

Freezing dryer is the most basic water removal equipment in compressed air post-treatment, but there are also different kinds of cold dryers, such as normal temperature cold dryer and high temperature cold dryer. The main difference between the two is that the high-temperature cold dryer is used to treat compressed air with intake air temperature as high as 60 C and 80 C, while the low-temperature cold dryer is often used to treat compressed air below 45 C..

Cold dryer

The temperature of compressed air is determined by the air compressor and ambient temperature. For the drying effect of cold dryer, the lower the intake air temperature, the better. Because the cold dryer is through freezing technology to reduce the temperature of compressed air liquefaction of gaseous water molecules, so as to achieve the purpose of drying.

The characteristic of high-temperature cold dryer is that it is equipped with a front precooler in the equipment, and the hot air with high temperature and humidity will initially cool down. When entering the heat exchange system of the cold dryer, do heat exchange drying treatment to ensure that the proper dryness can be achieved. In this design, the normal temperature cold dryer lacks a pre-cooler, and other structures are basically the same as those of the high temperature type.

Cold dryer

Generally speaking, if you can not use a high-temperature cold dryer, you should not use it. After all, you need more power consumption for drying treatment, which increases the cost of power consumption. Therefore, it is necessary to ensure that the ambient temperature and intake air temperature are kept in a relatively low environment. Generally, the air compressor is located in a factory building with good ventilation conditions, and the air compressor with good heat dissipation effect is selected at the same time.

Domestic air compressor products are miscellaneous and chaotic, which should be paid special attention to, because refrigerated dryers and air compressors are high power consumption equipment, and the operating cost also accounts for most of the total cost of the whole air compressor and cold dryer. Therefore, when choosing an air compressor, it is possible to save a large amount of expenses for the later operation if the energy-saving conditions are good. Choosing reliable equipment can reduce production energy consumption to a greater extent.