Tel

139-1322-1199

2022-12-21

Compressed gas engineering and equipment market development to today, manufacturing enterprises, equipment agents have been considering product innovation, technological change, each want to find a good market breakthrough method, has experienced economic "normalization" for many years how to interpret the market, how to promote products, more and more confused manufacturers, agents.

Stock market

The incremental market is transformed into the stock market, and the development of the stock market is the direction!

Developing customers in the stock market, implementing energy-saving transformation and energy management will be the next profit growth point.

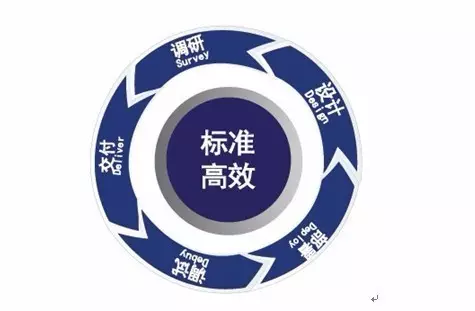

Implementation steps

Know the customer premise

Power consumption control

Accurately understand the overall energy consumption of the compressed gas system

Accurately understand the power consumption of each component and subsystem of the compressed gas system

SEE MORE →

Systematic holistic thinking

Fully understand the actual situation of the pipe network system, operating equipment and terminal gas used in the user's overall compressed gas system.

SEE MORE →

Clear scheme

"Tailor-made" energy saving plan for customers, clarify the energy-saving effect, explain the necessity and economy of the implementation of the plan with simple and easy to understand words such as figures and charts, highlight the advantages of their own products in the system, express the rationality and correctness of system improvement, fully communicate with customers at all levels to reach a consensus on the plan.

SEE MORE →

Large flow: centrifugal instead of screw;

Medium flow: two-stage compression replaces single-stage compression;

Small flow: frequency conversion instead of power frequency;

Low dew point requirements: cold drying instead of drying;

High dew point requirements: no gas consumption instead of gas consumption;

Pressure drop condition: increase pipe diameter;

Water content: detect the leakage point and the cause;

Storage tank capacity: according to 10% to 15% gas consumption Settings, as far as possible to use large capacity storage tanks;

Division principle: high and low pressure gas distribution;

Booster scheme: booster pump and booster are reasonably configured for gas terminal equipment;

Equipment environment: ventilation, cooling around the equipment and clean environment to reduce air dust;

Pipe network insulation: indoor and external pipe network systems pay attention to insulation;

Be prepared for continuous improvement and further optimization of the program, and do long-term customer service to improve the energy-saving effect.

Program implementation

Conscientiously organize the implementation of the contract signed by the consensus with the customer, organize the project team personnel, set up a special project leader and implementation personnel, according to the requirements of the contract, and constantly communicate with the relevant personnel of the customer during the implementation process, so as to get the understanding and help of the customer in emergencies, and complete the energy-saving implementation plan on time and according to the amount.

SEE MORE →

Verification of energy saving effect

After the implementation of the program, we will regularly provide customers with energy-saving effect reports, provide relevant personnel with the data compared before and after energy-saving transformation, and find out more energy-saving equipment and systems for customers to fully trust customers and facilitate the receipt of the final payment.

SEE MORE →

Sequence of scheme implementation

Find the source of leakage, stop leakage and reduce waste

Improve the use of gas terminal configuration, use new products to replace the use of gas waste

Find out the equipment of continuous gas supply to intermittent gas supplyFind a device that uses electricity instead of gas

Separate the equipment that requires high pressure, and provide pressurization equipment for high pressure gas separately

The test gas end has a lower operating pressure to reduce the equipment gas pressure

Replace the filter element in the filter in time to reduce pressure lossTo find the causes of enhanced pressure loss in the pipe network system and improve the pipe network structure

Determine the customer's real gas pressure and flow rate, and configure a reasonable number of equipment for customers

Reduce unnecessary energy consumption of gas purification, and do not blindly require water content

Constant pressure control for each part reduces pressure drop loss and replaces aging parts that cause pressure dropEquipment regular, regular maintenance and maintenance

Energy conservation focuses on industries and equipment

Tyre

Industry

Pneumatic mixing machine, cutting machine, lining extrusion, calender production line, forming, dynamic balance/non-roundness testing machine, etc.

Cars

Industry

Spot welding machine, cleaning machine, automatic stamping machine, pneumatic handling device, painting system, processing machine tool, transmission assembly equipment, etc

Semiconductor

Washing machine, wafer oxidation equipment, etching machine, sealing machine, various vacuum systems, pneumatic handling devices, etc.

Electromechanical

Processing cleaning machine, low pressure casting machine, finishing equipment, automatic assembly equipment.

Food

Industry

Blowing machine, filling machine, automatic feeding system, packaging machine, automatic inspection machine, baling machine, etc.

The market of energy conservation transformation or energy contract management will become a crowded scene, although you can simply sell a few equipment or replace a few accessories to do simple sales understanding, but can occupy this market will be more powerful, more high-tech, more for customers to create value for the team.